Custom Heating and Curing Systems for every industry

Infrared and UV-enhanced convection technology for the most cost-effective and risk-free improvements to your operations.

Higher Line Speeds, Lower Costs, Exceptional Quality Finishings. It’s a Win-Win-Win.

-

UV Curing Systems

An environmentally friendly alternative to conventional solvent-based chemicals.

Leading furniture brands have greatly benefited from our ability to replace laborious and expensive laminating processes with automated UV cured powder coating lines. These solutions not only increase throughput, they increase product quality and significantly reduce scrap rates.

-

Electric Infrared Heating Systems

Diverse systems for the automotive, electrical, heavy equipment, and general manufacturing industries.

Our engineers design custom equipment using various applications including powder and wet paint curing, bonding, melting, and specialty heating applications. You receive equipment that is optimized for your operating needs, instead of being forced to adapt to an inefficient heating system.

-

Gas Infrared Heating Systems

Industry leading precision heating systems for curing, drying, and melting applications.

With our innovations in heating technology, we are able to meet the level of control in a gas system that is typically reserved for electric systems. Our fuel-to-radiant output boasts the highest efficiency in the industry, resulting in significant savings for you over the life of your equipment.

Make the Switch and Stay Ahead of the Curve

Government directed doctrines are pushing manufacturers to switch to more environmentally responsible processes such as powder coating and water-based coatings.

Our infrared and UV radiation-enhanced convection technology is the most cost-effective and long-lasting method of implementing these environmentally driven improvements.

We Do It Right The First Time

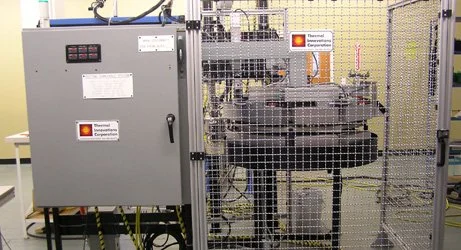

Since 1988 Thermal Innovations Corporation has engineered and manufactured custom heating and curing systems to your exact specifications. We use our technological know-how and expertise in radiation techniques to enhance convection heating processes for all markets.

Our worldwide strategic partner network provides you with access to suppliers of raw materials, coatings and sub-contractor manufacturers, as well as general contractors who service the production facility needs of the industry.

Our meticulous manufacturing process ensures you receive the highest quality equipment, with the lowest maintenance and energy costs for the life of your system.

Supercharge Your Convection Oven Systems

Operate an efficient, reliable system inside a 450 degree environment.

Trust our team to design and build complete thermal treating and processing solutions for your exact production needs.

Possessing an extensive background in modular design, full custom projects, and competence in multiple types of heating technology, we can bring together all of the design and engineering resources that your process or project requires.

With the experience in both small scale commercial and large, high production systems, we are remarkably flexible in the variety of industrial segments we can serve. We answer directly to performance requirements, speed and cycle time upgrades, physical size requirements, and can engineer to any level of necessary thermal precision.

We will work within your specific constraints while creating a comprehensive solution that does not compromise on thermal performance, process quality, or consistency.

Our Projects Speak for Themselves

Request a Proposal to Begin Your Project

Contact us to discuss your operations’ specifications and receive a timely, knowledgeable recommendation for which pre-engineered system kit will serve you best.